Testing Department

Ofar boasts a modern testing department, with the state of the art testing equipments. The Heat stability test machine for shafts up to 12 m in length is a quality assurance for forgings used in the power generation market.

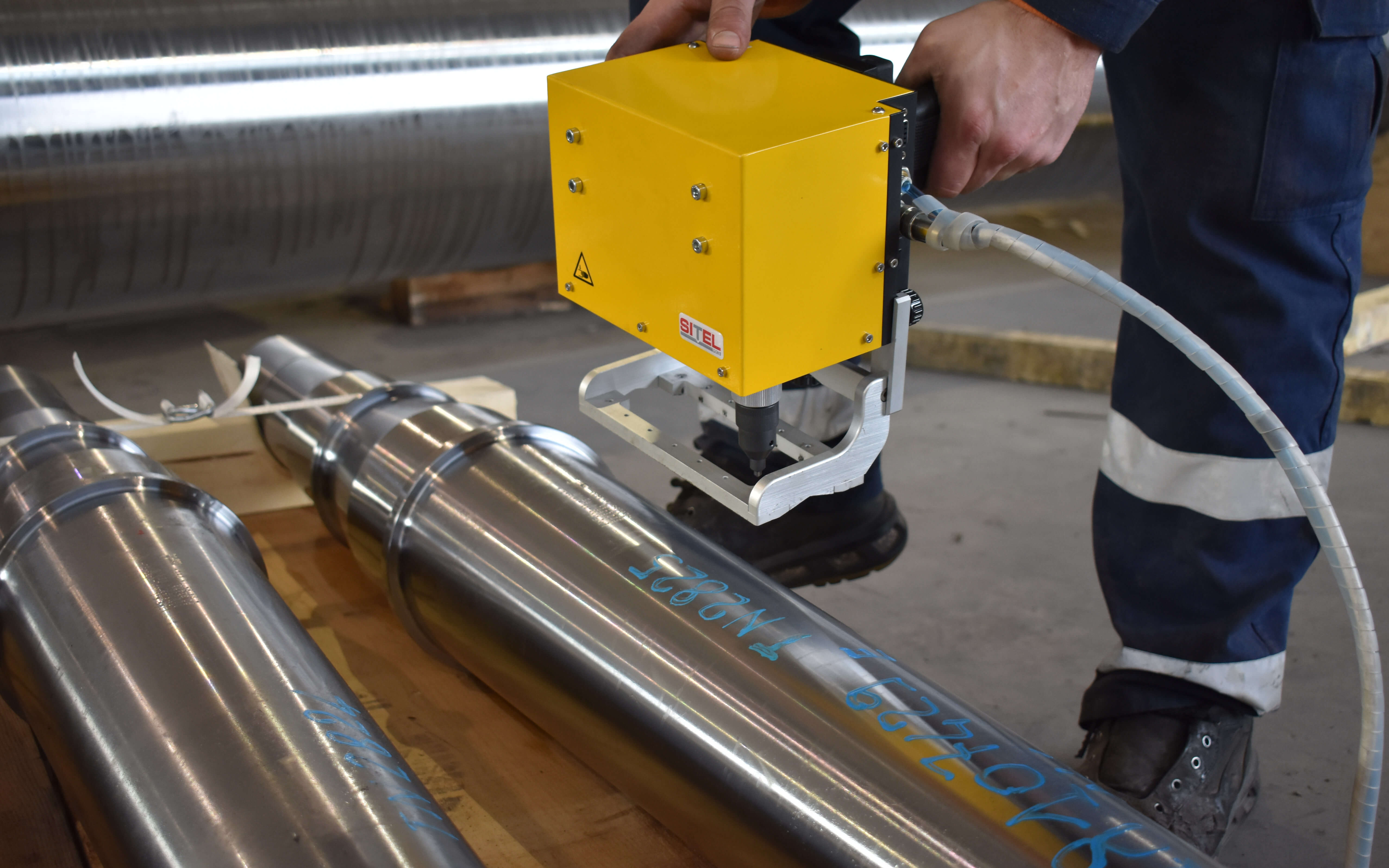

We carry out NDT with modern testing tools such as PMI, UT, dye penetrant, magnetic and borescope examination.

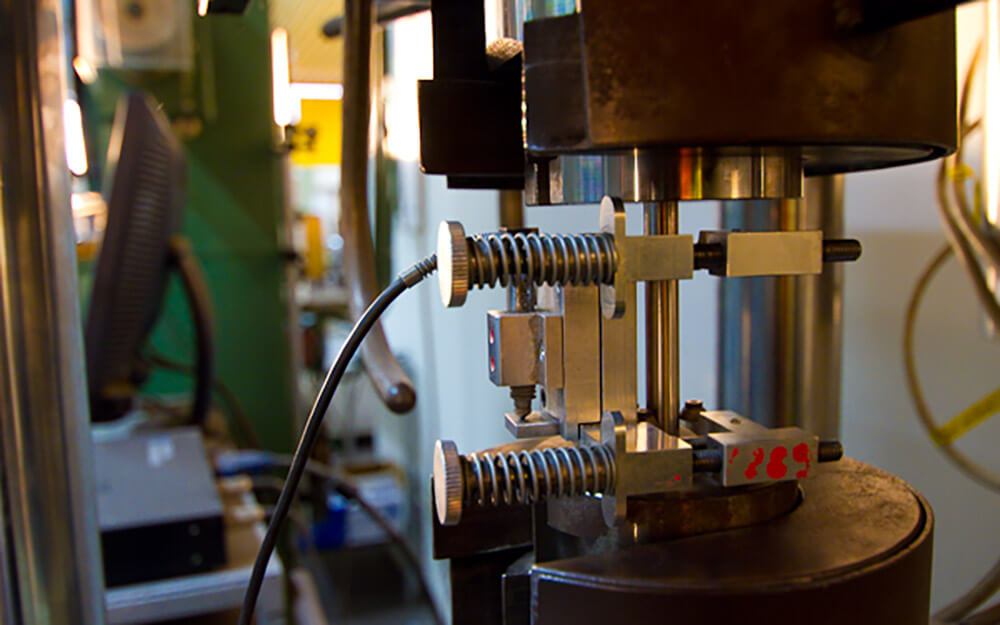

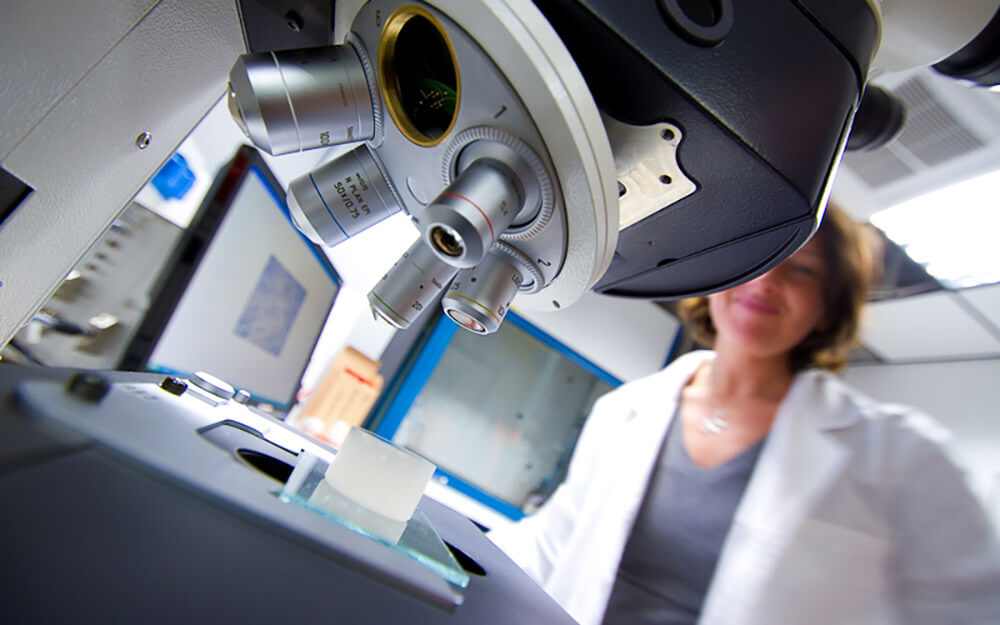

The quality of the forgings is guaranteed through accurate laboratory tests performed by highly qualified personnel and third level operators for UT (ultrasonic), MT (magnetic) and PT (dye penetrant). Destructive and non- destructive test are carried out in-house. The internal laboratory performs mechanical tests such as tensile tests, high temperature tensile test up to 1000 °C, Charpy tests at room temperature and up to -196 ° C, bend tests, hardness, rotating bending fatigue tests; the company can also perform and certify metallographic examinations such as inclusion state, austenitic grade, micrographies (x100th structures x1000), metallographic replicas and macrographies.

For more specific tests Ofar relies on external certified laboratories and partner Universities.